If you’re interested in doing your own joint repairs or other projects involving joining two metal parts, then you’ve probably started looking into welding. Someone pointed you towards MIG welding, and you are here to learn the MIG welding basics. Wonderful!

Table of Contents

Key Takeaways

- MIG welder uses a spool wire which is fed through the device and sticks out from the tip of your MIG weld gun to create an arc and a weld

- A shielding gas also goes through the machine to protect your weld from air contaminants

- Welder for MIG will allow you to adjust settings that you need for your metals and welds

- MIG welding most often uses a mixture of Argon gas and CO2 in a 75/25 ratio

- You can weld aluminum, carbon steel, copper, stainless steel, magnesium, nickel and bronze

If you’re curious about what MIG method is used for, or if you just want to know what is MIG welding, you’ve come to the right spot. We’ve got plenty of welding tips to turn you into a proficient user of the best MIG welder for novice welders!

In this article, you will learn every part of the process from beginning to end. Learn the techniques and positions, figure out the proper welding settings, and learn how to walk through the entire MIG welding procedure. By the end, you’ll be ready to get started!

MIG Welding Basics for Beginners

Metal Inert Gas (or MIG welder) unit uses a spool wire feed of dedicated wire thickness which is fed through the device and sticks out from the tip of your weld gun to create an arc and a weld. A shielding gas also goes through the machine to protect your weld from air contaminants and avoid weld defects. MIG welding is applicable to carbon steel, copper, stainless steel, magnesium, nickel and bronze. You can also MIG weld galvanized steel.

This is put simply but there’s much more to know about GMAW welding.

Knowing the right settings is important to a solid weld. This is an easy process, but you must set your machine up properly from amperage to wire feed speed. Make sure that you're aware of the settings you need for your metals and welds because unlike in Stick and TIG methods, you can't get away with welding when the settings aren't perfect. As for precision, a welding helmet with auto darkening feature will be of great help.

There is little room for any errors, so make sure you learn on several different machines. Is it difficult to learn how to weld and avoid the usual mistakes? Let's move on and find out all there is to know to become a skilled welder using MIG process.

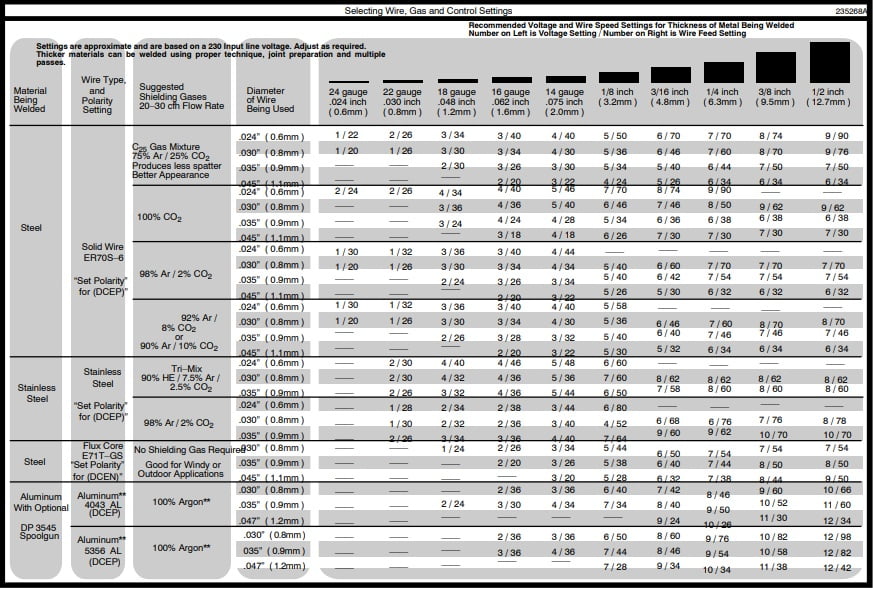

All welders usually come with recommended MIG welding settings like this one here:

As for the MIG welder settings for beginners, here’s a short but detailed video:

Safety First

Safety is critical for welding. Whether you're a professional or an amateur enthusiast, it is important to keep yourself safe in the garage. No one likes going to the emergency room and that is exactly what could happen if you're unsafe when you weld.

Protect your eyes and face using a welding helmet. Sparks will fly a lot of the time, and you need to know that your face will not burn. At a minimum, you will need to use some goggles to keep the sparks out of your eyes, but a a quality auto darkening welding helmet will protect you from the heat as well and enable you a clear sight of what you’re doing. In reality, a lot of welds cast a light that is even brighter than the sun, and you can't complete the project without being able to look directly at it.

You should not skimp on safety gear. Not just the mask, but your entire body needs to be protected. Weld jackets and aprons can cost a pretty penny, but they're going t help you a lot. Make sure that you are wearing flameproof clothing, so a stray spark won't ignite your outfit. The leather is the preferable material.

Quality welding gloves will also protect your arms from the sparks, so you won't get burned. Wear a welding shirt, apron, and chaps with thick pants and leather shoes or boots.

Even the smaller welders can draw a lot of power, so you need to make sure that your outlets and writing are capable of handling it. Circuit breakers aren't a great safety standard because there are plenty of ways for your garage to catch fire before a circuit gets tripped, thanks to the wiring heating up and setting fire to insulation.

You can easily test your equipment on a 110 system at nearly any hardware store. If you still don't know about it, it's worth paying an electrician to check out your workship and let you know if you need to upgrade it before safely welding.

A dedicated outlet might be worth installing because it's cheaper than replacing a burned-out breaker.

You also need to avoid the fumes that welds casts off because they are toxic. At best, you will get dizzy and nauseated. At worst, you can suffer from permanent neurological and physical side effects of prolonged exposure. Work in a very well ventilated area with enough airflow to ensure you're breathing in fresh air but not so much that it pushes away your shielding gas. If you notice that fumes are building up, take a break and leave the area for a while and leave the windows open and turn on some fans.

Keep Your Welding Materials and Workspace Clean

Cleanliness is vital in welding. Having a clean workspace will keep your project organized. On top of that, it can also keep you safe. With so much heat and power going through, nothing flammable must be near your workspace, or your entire workshop could go up in flames.

You also want to make sure that your area is cleaned because any dirt could lead to imperfections in your weld.

If your weld pool becomes contaminated with leftover dust and soot, your projects will have imperfections all over the weld. This makes for weak joints and massive issues.

You also need to clean your joints properly. Trust me, if your joint is dirty nothing you do will be able to fix that weld. If you put impurities into your weld joint, you will get a crappy result. Clean, clean and clean! This goes for MIG vs TIG welding and all other welding processes.

Metal Preparation for Welding

When it comes to welding projects, more than 75% of your work will be preparing to make the weld, rather than the weld itself. If you want a weld that will last a long time and hold strong, then it is critical that you properly prepare the materials.

You need to make sure that your surfaces are clean. This means removing any rust, paint, grease, dirt, and other contaminant materials before beginning your project. Use grinders, wire brushes, and compressed hair to remove the grime and strip your material down to a smooth and clean piece of bare metal. Do remove grease, rust and any dirt BEFORE using a brush because you will otherwise just smudge the contaminants all over the piece you're about to weld.

Never use chemical solvents to prepare or clean your metal unless you know that these solvents don't break down into poisonous gasses because when you begin melting and welding the metal, it will all be burned up and broken down. A lot of solvents also contain chemicals that will be left behind in your weld. These traces can break down inside the weld during the process and become harmful gasses.

You also need to clean the area where your welding lead will get clamped. That space should be able to withstand the electrical current load it will receive. Welding tables are great for this because you can quickly and easily clean a steel welding table and that material can absorb the necessary currents.

MIG Welding Equipment Preparation

Aside from safety equipment, you will need some other basic equipment to begin welding. First, you will need to choose the best MIG welding machine for your typical task. Pay attention to the amount of power it needs, especially if you’re planning on using it in a standard 110 voltage home outlet.

You want to buy a MIG welder that has enough power to be a workhorse but is also easy enough for a beginner to use. This will prevent you from being unable to operate your machine, but also prevent you from having to spend additional money trading up when you've got a better mastery of the skill.

You may also want to consider buying the following additional welding tools and accessories:

- Grinder: This will help you to bevel your edges and clean the nastiest grime from your metals before beginning a project. It's also useful if you need to break a weld and clean the base metal afterwards.

- Wire Brush Set: These will help you clean your metal before you begin your projects. If you have plans to do some MIG welding aluminum, you will also want a designated aluminum rush that doesn’t get cross-contaminated with any other brushes.

- Welding pliers: These will be very helpful when preparing and working with your project.

- Welding cart: This will let you place your welder on something stable. It helps make it easier to transport and keeps things easy to organize, store tools, and keep everything within easy reach.

- Cabinet for storage: If you don't want your tools in the open, finding a cabinet or cover may be a great way to offer them a designated space so they stay organized and don't get lost.

- Welding table: This offers a stable spot to work on your welding projects if they aren't already attached to the larger object (like a car) that you're working on, and allows you to adjust the project so you can pick ideal wire torch angles for perfect penetration.

MIG Welding Gas Selection

For MIG welding, you will most often use a mixture of Argon gas and CO2 in a 75/25 ratio. You can occasionally use a mix of Argon and Helium as a welding gas flow mixture.

Technically speaking, with active gases such as CO2, MIG ( metal inert gas ) is not the right term as carbon dioxide is not an inert gas like Argon and Helium but active, so the right term is GMAW – Gas Metal Arc Welding. In the arc welding process, two base materials are joined together by feeding a continuous solid wire electrode via a welding gun and into the weld pool.

As for your flow rate, it needs to match your wire and material, but it is oftentimes set to 20 to 30 cubic feet.

Most common Argon mixtures when learning the welding basics of MIG welding are:

- 95% Argon + 5% Co2, for welding up to 8mm steel

- 90% Argon + 10% Co2, for welding from 8-25mm steel

- 80% Argon + 20% Co2, for welding 20mm plus steel

- 75% Argon + 25% Co2, for most MIG welding works

The disposable cylinders contain a mixture of 86% Argon + 14% Co2 mix.

And the inert/active difference? Well, Argon is an inert gas which simply provides shielding as it replaces the air around the weld and protects it from the contaminants (Oxygen, nitrogen and hydrogen). Active gases have an effect on the welding process and the welds themselves: CO2 makes the gas electrically conductive, which in turn raises the arc voltage and increases penetration.

Active gases are mainly used for GMAW welding most metals except Aluminum which needs pure Argon.

Welding Wire Stick-Out

The wire stick out for a weld should be around ¾ of an inch. You can do a little less, but if you do more than that your shielding gas can't do its work. The flow rate of your gas also needs to be correct for the stick-out.

The welding wire stick-out for MIG welding should be around ¾ of an inch. You can do a little less, but if you do more than that your shielding gas can't do its work to protect base metal materials you're trying to weld.

The flow rate of your gas and wire feed speed also needs to be correct for the stick-out.

Push or Pull?

There are 2 different types of MIG welding. The most common is to push (forehand) the gun towards the weld at the right speed. This will give you shallow penetration for a smooth and flat surface.

The other method is backhand, where you drag (or pull) the gun away from your weld in a similar fashion to Stick welding. This method provides a deeper penetration that is narrow and high in the center. But is MIG or stick welding stronger regardless of the technique? The experience says stick, especially when it comes to thick metals.

Most of the time, MIG welding will use the forehand method. This means you will be pushing your gun towards your weld at optimal speed. This is because the pull method exposes your weld project, while the pushing method allows the shielding gas to work properly.

Flat Position

Flat welding position is the easiest type to master. The gun gets pushed at a straight down angle that leans towards the direction of the weld at any angle up to 35 degrees. A high voltage setting that runs fast and hot is ideal. Use a steady motion in any pattern that will penetrate the weld. If you're new, crank the setting up high.

Horizontal Position

This technique is a bit harder than flat welding. In this method, your MIG gun is pointing upwards between 35 to 45 degrees at a 15 to 35-degree tilt towards the direction of your weld. Make sure that you don't overlap or roll the weld over in this welding position. Use tight stringer beads for the weld joint. Whipping and circles are the best tactics for this position. You must have skill here because adding heat to your machine won't compensate for poor technique. Your weld must be spread out.

Vertical Positions

Vertical down welding is also relatively easy to learn and use. Start on the top and work downwards. Tilt your MIUG gun upwards between 35 and 45 degrees. The trick to this method is making sure you stay ahead of your weld puddle and keep your electrode moving side to side. If you don't, you won't get enough penetration to properly build your joint.

Of all the MIG positions, the vertical up position is the hardest to master for MIG welders. Your gun points up between 35 and 45 degrees and you will need to build a shelf of weld to work from. This weld is convex. Grind a small groove where you’re going to weld metal because no matter how you weld it’s going to be nearly impossible to make it look right.

Overhead Position

Overhead technique will put your gun at a 5 to 35-degree tilt in the direction of your weld. The heat should be very much on the hot side. Once you get used to this it becomes as easy as flat welding.

This method will increase spatter falling, so you need to make sure you keep your sparks controlled and away from you. Make sure to tuck in your sleeves so you don't end up with molten metal burning your skin.

The More You MIG Weld, the Better the Results

Finally, remember that practice really does make perfect. The more you weld the more you will start to get used to the feel of your gun and the positions.

You'll learn better technique and build up muscle memory. If your first few welds don't come out perfect, don't give up! Practice with an affordable multi-process welder like Forney Easy Weld 140 MP which won't break the bank.

Go over basic MIG practice welds as many times as needed and just weld! Move on to completing formal training and obtain a welder certification.

Will your welder salary justify your efforts? I believe it will!

FAQs

1. What are the four fundamental elements of a MIG setup?

The four fundamental elements of a MIG setup are:

- Power source- any MIG machine's power supply is its most important component because it regulates numerous torch variables.

- The welding torch - sometimes it is called a MIG welding gun,

- MIG welding wire - is essential to the MIG welding process.

- Earth clamp or ground clamp

2. Does MIG welding include pushing or pulling?

The rule in this instance is straightforward: you drag if it generates slag. In other words, when using a stick or flux-core wire welder, you drag the rod or wire. Otherwise, you can weld with metal inert gas (MIG) and force the wire. The wire speed is also important.

3. What are the 8 typical MIG welding errors?

The 8 typical MIG welding errors are:

- An improper distance from the contact tip to the workpiece

- Issues with drive roll and bad wire tension

- Wrong voltage for the wires and/or wire speed

- Issues With Gas Flow

- Difficulty Understanding Bead Patterns

- Issues With Travel Speed

- Warping

- Failure to prepare your metal

4. Is MIG welding AC or DC?

MIG welding is DC. Although a MIG welder normally operates in DC mode, many other stick welding machines, including some TIG welders, also use DC, particularly when joining stainless steel with a TIG welding machine.

5. Can I MIG weld without gas?

No, you can not MIG weld without gas. Despite the fact that MIG welding requires gas, it is entirely feasible to weld without carrying a gas cylinder and other equipment. For many hobbyists, self-shielding welding with flux core wire is a fantastic alternative, and with the correct welding equipment, you may get fantastic results!