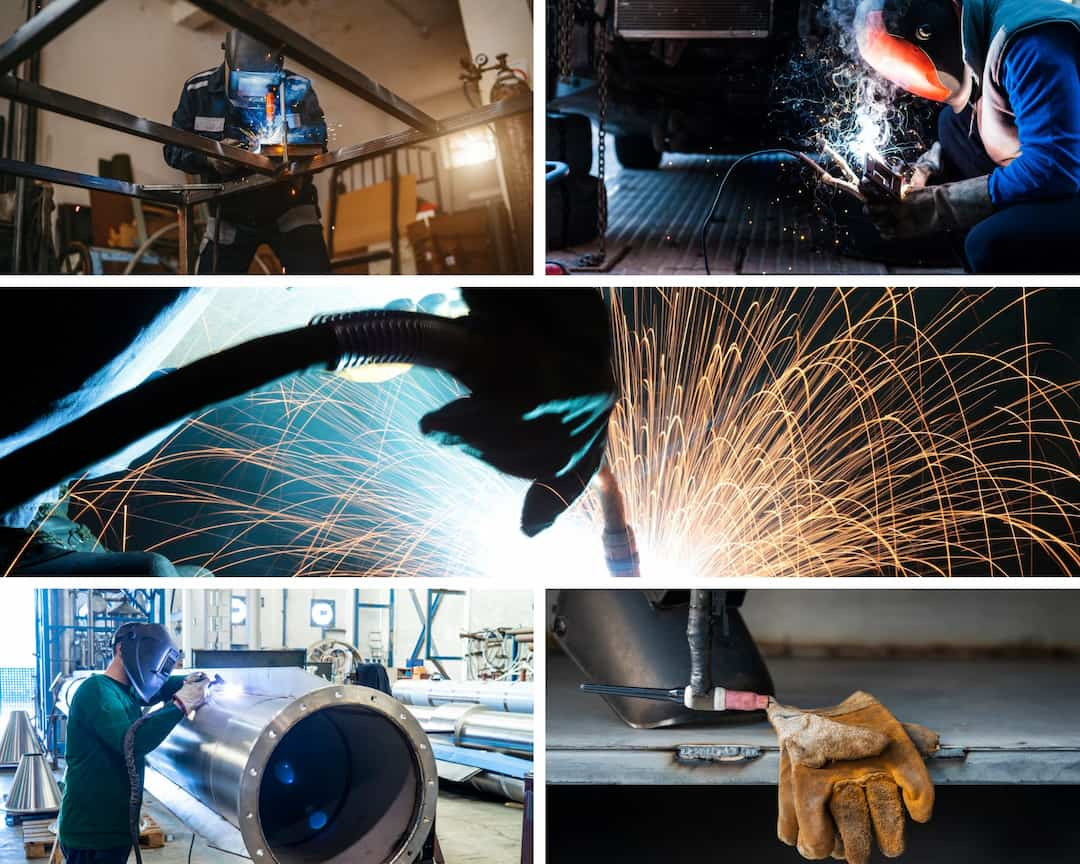

Do you ever look at welders and wonder what it takes to become one? If so, you’re not alone. Welding is a crucial profession that makes our world run—from aircraft to automobiles, from ships to skyscrapers but does it take a unique skill set? Is welding hard to learn or can anyone learn this widely appreciated trade?

Table of Contents

In this blog post, I will explore whether welding is hard to learn and how long it takes for someone new to master the craft.

Through facts about welding, interviews with industry experts, and insights from current welders who faced challenges when learning the ropes of welding, I will provide all aspiring welders out there an in-depth look into what it takes to become a certified professional welder.

Key Takeaways

- It can be hard for someone to learn how to weld as it requires skills and attention to details but with enough experience you can become a professional welder if you set your mind to it.

- Spending time with professionals and watching them welding using various methods makes it a lot easier to learn how to weld.

- You can also learn how to weld easily by attending welding school or by learning some basic welding techniques by watching videos just to get to know the basics before tackling practical work hands-on.

So, Is Welding Hard to Learn?

Well, it depends on the welding type you are going to do, the skill level of the welder and what materials you will work with. Welding is considered a skilled passion; it takes practice to become a professional. It can be tough to learn it if you have no experience but it is possible if you try and give your best.

You can count welding as a complex technique that requires precision and skill. Many of the techniques used in welding require practice to master so even after you learn how to weld it's important to hone your skills and continue learning. Getting a combo welder like Miller Multimatic 220 can help you master MIG, TIG and stick welding processes using a single welding machine,

What Will Make Welding Easier to Learn?

I will suggest a few things so you can work on them to make the learning process easier. First, choose reliable resources when researching welding techniques, materials, and safety procedures. Familiarize yourself with the different types of welding processes by reading books or taking classes it is helpful believe me. Get access to the right equipment and supplies to practice welding in a safe and controlled environment.

Make sure that your workspace is well-ventilated, comfortable, and well-lit. It is also beneficial to have a mentor who is experienced in welding and can answer questions as they arise.

Finally, be patient with yourself and have fun—learning to weld takes time, but it can be an incredibly rewarding experience. In case of mistakes, you also need to learn how to break a weld so that you can redo the work.

Can I Teach Myself to Weld at Home?

Yes, it is possible to teach yourself to weld at home. To get started, you'll need the proper equipment and safety gear. Start by researching different types of welding methods, such as using a MIG welder, TIG, Stick, and Flux Core. Each type has its unique process and skill set that must be learned to weld properly and safely.

Once you’ve decided on the welding you want to learn, purchase the necessary equipment. Depending on the type of welding you choose, you will need a welder, safety gear such as gloves and goggles, filler metals or electrodes, fluxes, and other tools.

It might take much more practice and dedication to become proficient in welding than you think. You will need to know the basics of safety before attempting any welding. Invest in quality equipment and protective gear to ensure your safety when welding.

One of the best ways to learn to weld is by taking a class or course that offers instruction on safety, proper techniques and equipment use. You can also find plenty of tutorials online that offer step-by-step instructions for welding various materials via various methods. It’s important to practice as much as possible to become skilled at welding.

Find a designated, safe area in your home to practice welding. Make sure the area is well-ventilated and free of debris and flammables.

Common Types of Welding

Several different types of welding can be used for various applications. The most common one is stick welding which uses an electric current to heat and combine two pieces of metal with . Other popular methods include MIG welding,

Flux Core, and tungsten inert gas welding - TIG. Each of these method or type has advantages and disadvantages, depending on the desired outcome and how you apply them. I am going to explain these types of welding here:

1. Stick welding (also known as shielded metal arc welding)

Stick welding is a process that uses an electric current to create an arc between two pieces of metal, which heats and melts the metals, allowing them to fuse. SMAW method is often used for thicker materials, requiring less precise joining techniques than other methods like Flux Core, MIG or TIG welding. Advantages of arc welding include its affordability, availability in different materials and thicknesses, and flexibility.

2. MIG Welding:

MIG (metal inert gas) welding is a semi-automatic process that uses an electric current to heat the metal and join two pieces together. A MIG welder uses a wire electrode fed through a special gun to form an arc between the two pieces used to melt and fuse them. It's a popular choice for thinner materials due to its precision and speed.

3. Flux Core Welding:

Flux Core welders use a wire spool coated in flux to create an electric arc between two pieces of metal. This arc is used to heat and melt the two pieces, allowing them to be joined together. It's a popular choice for outdoor projects due to its ability to work in windy conditions and on rusty metals without the use of shielding gas.

4. TIG Welding:

This type of welding is a more precise manual welding process often used for thinner materials. It uses a non-consumable tungsten electrode fed through a hand-held torch to form an arc between the two pieces creating a very precise and clean weld. This method requires a higher skill level than other methods, making it more difficult and allowing for greater accuracy.

Is Stick Welding Hard?

Stick welding, or shielded metal arc welding (SMAW), can be a difficult skill to master, but with practice and patience, it is achievable. The difficulty of stick welding depends on several factors, such as the type of material you are working with or welding tools, the setup of the equipment as weld steel, welding wire, or filler rod, and your welding skills.

For starters, stick welding requires a higher level of skill than MIG(metal inert gas) or TIG(tungsten inert gas)welding. With stick welding, you must maintain a consistent arc length and proper electrode angle to ensure the weld is successful. You must also know how various environmental conditions, such as wind, temperature, and humidity, affect your welds.

How Much do Welders Make?

A welder can make a good living depending on their experience, location and the type of welding they specialize in. In the United States, $19.12 an hour is the hourly pay for welders in 2023.

Experienced welders can earn a much higher salary than the median while entry-level welders may make less. In addition to their base pay, many welders have access to benefits such as health insurance and 401(k) retirement plans.

FAQS Related to Is Welding Hard to Learn

How long does it take to learn to be a welder?

The amount of time it takes to learn to be a welder depends on the welding you plan to do and your experience level. Generally speaking, training and practice can take anywhere from a few months to several years or more before you become a proficient welder.

What’s so hard about welding?

Welding is a craft and an art, so it can be challenging to master. It requires skill and practice to understand the every physical principles behind the process and have a good eye for detail. Additionally, welding involves high temperatures, extreme conditions, and hazardous materials that require proper safety precautions making it important to have proper training and the right equipment.

Is welding school worth it?

Attending welding school is beneficial in many ways. You will learn the fundamentals of welding and gain hands-on experience with different equipment, tools, and processes. Welding schools also provide safety training and educate students on the latest industry regulations. This can be invaluable to starting or experienced welders looking to expand their skill set.