MIG welding galvanized steel is a great way to make sure your projects stand the test of time. It’s a process that can be overwhelming, however, with all the different kinds of metals and techniques involved. Understanding what you need to know before attempting such a project is essential in order to get the end result you’re aiming for.

Table of Contents

In this blog post, we will go over why it’s important to consider MIG welding galvanized steel versus other types and share some tips on how best to approach your project. Keep reading if you want to know more about how you can successfully weld galvanized steel!

Key Takeaways

- Galvanized steel offers greater protection against rust and corrosion than other types of metals.

- It is important to take the necessary safety precautions when MIG welding galvanized steel, as it can release hazardous fumes.

- Before starting your project, you should make sure that all materials are properly cleaned and prepped for welding.

- Use the correct type of filler metal and the right settings on your MIG welder to ensure a strong, well-made weld.

- MIG welding galvanized steel is an effective method but you must take extra care when using it to ensure that you get the best possible result from this welding process.

What Is Galvanized Steel and How Does It Differ from Regular Steel?

Galvanized steel is a type of welding metal that’s been coated in a protective layer of zinc oxide. This makes it much more resistant to corrosion and rust than regular steel.

The zinc acts as a barrier, protecting the underlying metal from damage caused by moisture and other elements in the atmosphere. This makes it an ideal choice for projects that will be exposed to the elements, such as outdoor furniture or construction applications.

What Type of Welders Can You Use to Weld Galvanized Steel?

Stick welding is by far the most popular method to weld galvanized steel. It's also perfect for beginners as it is simple as well as fast. When using a stick welder, always weld outside to avoid toxic fumes. In addition, you should put on a welding respirator for maximum safety. The most popular stick welding rods for galvanized steel stick welding process are the E6011 and the E6010.

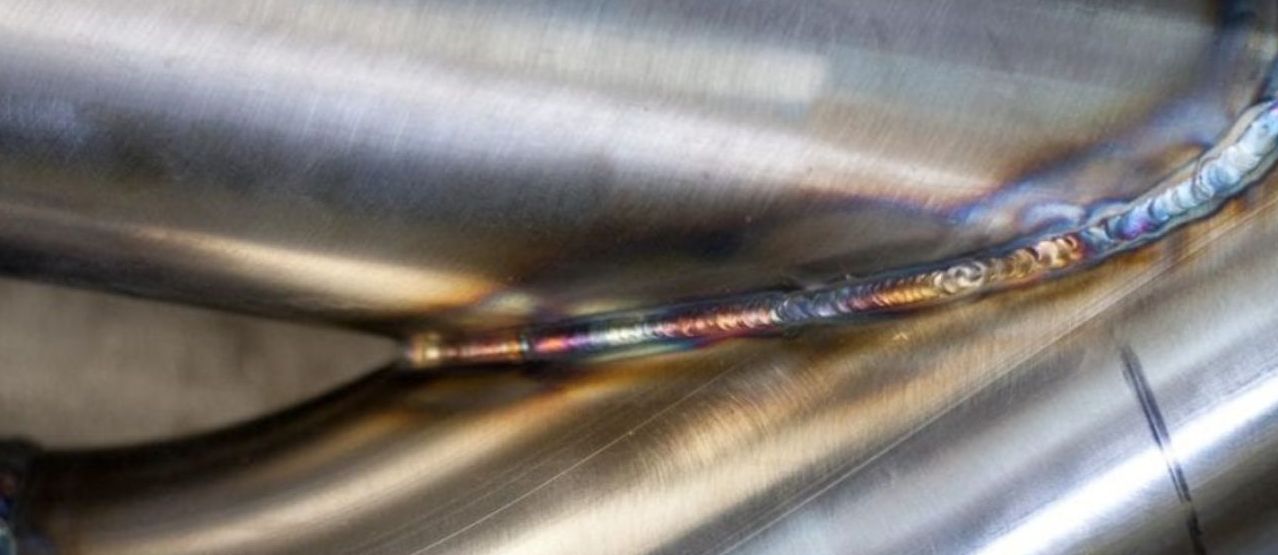

MIG welding is another commonly used type of welding galvanized steel. The process involves using a reliable and efficient MIG welder to heat and melt the steel, creating a strong bond between the two pieces of metal.

The key to successful MIG welding of galvanized steel is removing metal coating and using the right type of filler metal and also making sure that your MIG welder has the correct settings.

Using a good flux core welder is another cost-effective method for galvanized steel welding projects. The best flux core wire commonly used is the E71T-GS.

Which Wires to Use for MIG Welding Galvanized Steel?

When MIG welding galvanized steel, there are specific types of wires that are commonly used due to their effectiveness in this application. Here is a list of wires used for MIG welding galvanized steel, along with their nomenclature and short benefits:

ER70S-6: This is a commonly used solid wire for MIG welding galvanized steel. It is a mild steel wire with a high level of deoxidizers, making it suitable for welding on galvanized surfaces. Benefits include good weldability, smooth arc characteristics, and minimal spatter.

ER70S-3: Another solid wire option for MIG welding galvanized steel, it is also a mild steel wire with a higher silicon content than ER70S-6. This wire offers good performance on galvanized surfaces, providing good wetting and penetration. It produces a smooth and clean weld bead.

E71T-11: This is a flux-cored wire that is often used for welding galvanized steel. It has a tubular design filled with flux, which provides shielding gas and deoxidizers, eliminating the need for a separate shielding gas. It offers good weldability, high deposition rates, and is suitable for welding thicker galvanized materials.

E71T-GS: Another flux-cored wire commonly used for MIG welding galvanized steel, it is similar to E71T-11 but has a self-shielding gasless design. It is ideal for outdoor applications where it may be difficult to use a shielding gas. It provides good penetration and weld quality.

NR-211-MP: This is a versatile flux-cored wire that can be used for welding galvanized steel. It is designed to handle a wide range of materials, including galvanized surfaces. It offers excellent performance, good bead appearance, and smooth arc characteristics.

Benefits of using these wires for MIG welding galvanized steel include good weldability on galvanized surfaces, excellent wetting and penetration, minimal spatter, smooth arc characteristics, and the ability to handle a variety of galvanized materials. It's important to note that when welding galvanized steel, proper ventilation and precautions should be taken to avoid inhaling extremely toxic zinc fumes.

Safety Tips for Welding Galvanized Steel

It is important to take safety precautions when working with galvanized steel, as it can release hazardous fumes when heated. Here are more some tips to keep in mind when MIG welding galvanized steel:

- Wear the proper safety gear, including a reliable welding helmet, gloves and a respirator.

- Work outside or in a well-ventilated area.

- Ensure all materials are properly cleaned and prepped for welding.

- Use the correct type of filler metal and the right settings on your welder.

Different Techniques for Making Stronger and More Durable Welds on Galvanized Steel

When it comes to MIG welding galvanized steel, there are a few different techniques you can use to ensure that your weld galvanized steel bonds are strong and durable. Here are some of the most common techniques to consider:

Use a backing strip or plate when welding thinner metals. This will provide extra support and strength to the weld.

Use a lower welding current when welding galvanized steel safely, as this will help reduce the amount of heat that is generated.

Use a stepped welding technique, alternating between long and short welds. This will help to ensure that the weld is even and uniform in strength.

Common Mistakes That Should be Avoided When Welding Galvanized Steel

While to MIG welding galvanized steel, there are a few common mistakes that should be avoided. The first mistake is using the wrong welding technique. Because of the zinc coating on galvanized steel, it is important to use an gas metal arc welding process rather than a gas welding one.

Additionally, it is important to use a higher amperage than normal. The second mistake to avoid is not cleaning the area after welding. It is critical to remove all slag, dirt, and grease from the welding area in order to prevent further corrosion.

Lastly, it is important to avoid over-welding. Too much heat can cause the zinc galvanized coating to break down, leading to corrosion and further damage.

Conclusion

In conclusion, when it comes to whether you can MIG weld galvanized steel, the short answer is yes you can. However, there are various factors that must be taken into consideration to ensure optimal safety and outcome of the weld.

There can be benefits to welding galvanized metal such as preserving the strength of the weld joint while providing a neat-looking finish and a measure of cathodic protection from corrosion.

When attempting this type of work please remember to use proper ventilation and wear personal protective equipment (PPE) at all times, even if the welding machine has some sort of gas emission controls installed for your safety.

Frequently Asked Questions

Is it safe to MIG weld galvanized steel?

Yes, it is safe to MIG weld galvanized steel. However, you should always take the proper precautions such as wearing the appropriate safety gear and working in a well-ventilated area. Additionally, you should use the correct type of filler metal and settings on your welder to ensure the best outcome.

Can you MIG weld galvanized steel without a shield gas?

No, it is not recommended to MIG weld galvanized uncoated steel without a shielding gas. Shield gases are necessary to create a protective atmosphere around the weld, which helps to reduce oxidation and improve the strength of the weld.

Is it necessary to pre-heat galvanized steel before welding?

No, it is not necessary to pre-heat galvanized steel before welding. However, it may be beneficial to do so in order to reduce the chance of cracking and other issues when welding. It is important to note that pre-heating will also increase the amount of time needed for the welding process.

Can MIG welding galvanized steel be done indoors?

Yes, you can MIG weld galvanized steel indoors. However, it is important to make sure that the area is well-ventilated in order to avoid inhalation of any welding fumes. It is also recommended to use a fume extract or metal fume fever hood to help reduce the amount of zinc fumes.

Is flux cored wire suitable for MIG welding galvanized steel?

Yes, flux cored wire is suitable for MIG welding galvanized steel. Flux-cored wires designed to reduce the amount of spatter and increase the strength of the weld, making them ideal for welding galvanized steel.

Here’s a helpful video how to de-galvanize steel!