Welding is an essential skill in the modern world, and welding safety is not a joke. Experienced welders are responsible for fusing together substances like metal and synthetics to create strong bonds and durable equipment.

Table of Contents

Unfortunately, there are many potential hazards and welders put themselves at risk of long term or even permanent injury. For example, it is common for individuals to burn themselves, damage their retinas from light, or inhale toxic fumes while working with unstable materials.

Key Takeaways

- Welding process involves intense heat so make sure you don't get burned

- Always protect your eyes with a welding helmet, safety glasses or goggles

- Avoid exposure to fumes and gases by using a respirator

- Wear a proper protective gear, helmet, apron and gloves

- Be aware of your immediate surroundings while welding to prevent accidents

To avoid issues, it is important to adhere to proper welding safety standards. Whether you are an amateur or experienced, make sure to follow the following welding safety tips to avoid accidents and injuries on the job.

Why is Welding Safety Important?

Professional welders hold an occupation with one of the highest annual injury rates. This is because the welding process involves intense heat, light, and energy that can primarily result in burns and similar injuries. Although there is always the risk of getting hurt, adhering to proper safety instructions lessens the chances of a severe and even permanent injury occurring. Welding in unsafe conditions can even lead to death, especially when working with fumes that are toxic and chemicals.

To ensure personal wellbeing and avoid getting a career ending injury, make sure you remain up to date with welding safety protocols and are using your equipment properly.

Protection For Your Eyes Is a Must

One of the most frequent injuries is permanent eye damage and even burned retinas. These injuries occur when someone is not wearing proper eye protection and exposes themselves to the intense bursts of light common during welding arc.

However, it is also possible to damage the eyes by not wearing a mask or safety glasses and being burned by the sparks that fly from metal. Some individuals can also receive an injury from fumes that are toxic and even shrapnel. To avoid any eye injury, make sure you are wearing an industry standard set of goggles or the best welding helmet you can afford.

Always Wear Regular or Auto-Darkening Welding Helmets

A proper welding helmet is an essential tool of the trade. These helmets shield the entire face from heat and sparks and include special lenses that enable the wearer to see despite the flames and sparks. Auto darkening welding helmets are rapidly becoming popular because the lens transitions from bright to dark while you weld, making it easier to see despite changing conditions.

The average auto darkening helmet will quickly transition from a shade level of 3 to one of 11 in a few seconds. If you do not work well with sudden light adjustments, many modern options now include a short twilight phase that allows your eyes to adjust without being damaged.

Potential Eye Injuries Are One Hazard of Using GMAW Equipment.

Arc flash is not a joke. Many afflicted welders describe it as feeling like hot sand is burning your eyes. It can cause permanent damage to your retinas and affect your vision for the rest of your life, which is why the majority of helmets now auto darken.

Never try to weld without protecting your eyes from sparks and the flashes of an arc weld. Most regular and auto darkening helmets can be purchased for less than $200 and will last for years.

Avoid Exposure to Fumes and Gases

There are multiple types of welding, and some forms expose the professional to potentially toxic fumes that have lasting health effects on the individual. Gas or oxy-fuel welding uses a flame from burning a gas. These gases can cause eye and throat irritation, vision damage, and even cancer.

The best way to avoid exposure to fumes and gases is to work in a well-ventilated area and to use equipment which is maintained and up to date with all industry safety regulations.

Wearing respiratory protection is also essential, and the protection should cover the mouth and nose. A good respirator forms a tight seal around your face and does not have noticeable gaps. If you have a beard or mustache, you might need to trim it to get an accurate seal with the average respirator.

Physical Hazards Welders Encounter

There are numerous physical hazards welders encounter in their daily jobs. Some of the most common include burns, eye damage, electric shock, cuts, and injury to toes and fingers. Long term professionals can also develop muscle or tendon damage from holding their hands in the same position for extended periods of time.

To avoid these most common welding hazards, make sure you wear a mask and gloves at all times and also have a safe suit to wear. If you start to feel muscle strain, switch positions and make sure to stretch on a regular basis. Do not weld without your equipment.

You can avoid many physical injuries by being aware of your surroundings. If the materials you are working with start to feel wobbly or insecure, stop what you are doing and make the proper adjustments. If your clothing starts to slip or move out of position, turn off your welder and readjust.

Finally, NEVER point your equipment at another worker close to you. You might be joking, but injuries can and do occur because someone was horsing around with industrial equipment.

Beware of Electric Shocks, Fire and Explosion

Electric shocks are a common physical hazard and can occur when you touch a part of the welding or electrode holder circuit. Shocks also happen if your equipment is damaged or you are trying to weld in wet conditions. Keep your equipment properly maintained and never work in water unless you are wearing proper gear for such conditions.

At the same time, beware the risk of fire and explosion. You should never weld around flammable chemicals and should always be aware of where the sparks from the welder are headed. Avoid working around highly flammable materials like dry wood, paper, or oils.

To further avoid fires and especially explosions, make sure your workspace has adequate ventilation and fire alarms, is properly ventilated and fumes are not building up in the air. This can be done by having well-maintained vents and keeping a close eye on any gases or toxic materials in the area. You should also consider having fire extinguishers near and flame resistant clothing.

Button Up When At Work

This is one of the most common sense safety standards but also one people tend to ignore. One of the greatest welding safety hazards is the flying sparks that are seen when working with metal or trying to arc weld. While they don’t always seem dangerous, they can cause serious burns along the stomach and chest.

Avoid injury and keep your uniform fastened and buttoned. Even if you are hot, it is better to be sweating than to be burned or hospitalized. If you are seriously uncomfortable, turn off your equipment before making adjustments.

Wear the Proper Protective Gear

You need to wear the proper gear to avoid common welding dangers. No matter what type of welding you perform, the right gear will always include a mask with a fitted lens, welding gloves, and a suit capable of protecting you from sparks. Some forms like gas welding will also necessitate you wear a respirator to avoid breathing in fumes that are toxic and putting yourself at risk of respiratory system damage.

If your equipment does not fit properly, turn off your welder and readjust. Never try to adjust while welding. Your gear should only be worn by you and should include a full set of items. In addition to the clothing mentioned above, also make sure you have the right shoes.

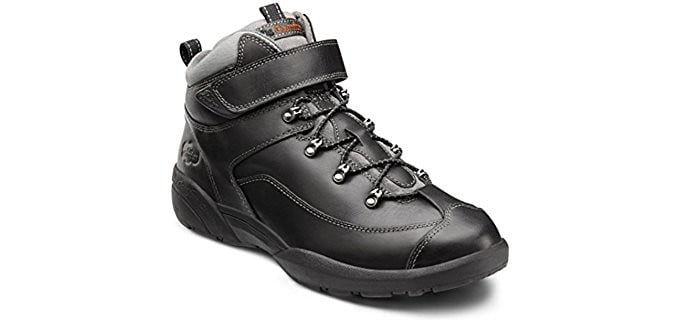

The Right Shoes

The right shoes for welding are comfortable, durable, and do not put the wearer at increased risk. Make sure your boots are made from non-flammable material and have a reliable, heat resistant outsole to avoid melting or burning on the job. A metatarsal guard will add extra protection for your toes.

There is significant debate about whether or not it is better to have boots with or without laces. If you choose to have laces for a better fit and comfort, make sure they are tucked into the shoes so you do not trip.

Breathe Freely

Breathe Freely is a campaign dedicated to reducing worker exposure to fumes that are toxic during the welding process. In addition to providing resources to industry leaders, the campaign website offers numerous educational guides and pamphlets. These explain how welders like you can reduce their risk to the dangers of welding.

Avoid Repetitive Stress Injuries

Avoiding repetitive stress injuries is one of the most difficult parts of working in the industry. Stress injuries occur when an individual forces their body to perform the same action over and over, or when the body needs to maintain perfectly still and strained for an extended period of time.

To avoid stress injuries that are repetitive at work, always stretch before and after welding sessions. Make sure your equipment fits properly and is not too heavy. Finally, know when to take a break. If you are in pain, stop what you are doing.

Lose the Clutter

Clutter is a safety hazard. Keep your workstation neat and clean by storing personal belongings in a nearby locker or employee area.

Do not bring food and drink into the section where you weld and remember to clean up after yourself. If you spill something, mop it up.

Most importantly, never bring flammable materials to your workstation. These include standard items like paper but also chemicals and compounds like oil and gasoline.

Use Boom-Mounted Wire Feeders

One major occupational safety tool is the recent implementation of boom-mounted wire feeders. These are an advanced form of welding equipment which safely stores necessary materials and declutters the workspace. It cuts down on how much time you need to perform non-arc welding activities and provides a good range of motion for work.

The majority of industrial welding workstations now use boom-mounted wire feeders. If you do not have one, consider investing or asking your manager for one to improve workplace safety conditions.

Summary of Welding Safety Precautions

As you can see, there are many welding hazards which can be avoided with proper welder protection, safety precautions and careful attention to detail. Here are the three main points you should take away from this brief welding safety overview.

Always Wear Appropriate PPE

The most important rule is to always wear appropriate PPE. This means having the right clothing, a sturdy pair of boots, heat and flame-resistant gloves, and proper arc welding eye protection. Such items need to be replaced on a regular basis.

Receive Appropriate Training and Use Tested, Reliable and Quality Welding Machines

Make Sure Your Workspace is Well Ventilated

If you are gas welding or working with unstable materials or toxic gases, always make sure your workplace is well-ventilated. This means having fans ( roof exhaust fans and wall fans ), adequate ventilation where the vents open to the outside, and even wearing a respirator and similar breathing equipment. Never work in a confined area or breathe in chemical fumes for an extended period of time.

Ensure Your Workspace is Free of Flammable Material

Finally, one of the most proper precautions are making sure your workplace is free of flammable material. Welding utilizes gases, heat, flames, and sparks that can easily result in a fire. You do not want to fuel a potential fire by working around gasoline, oil, and similar materials.

Most importantly, remember to stay safe and never work in an environment where you are uncomfortable with the work laid before you. Always make sure you are experienced and working with well-maintained equipment, and do not violate common sense.

FAQS

1. What are the 10 safety rules when welding?

The 10 welding safety guidelines are:

- Carry out in a recognized safe area.

- Take steps to avoid fire risks.

- Analyze the dangers.

- Maintain your equipment.

- Use the appropriate PPE to protect yourself.

- Verify the ventilation.

- Avoid breathing in vapors and fumes.

- Protect your coworkers.

- Read the warning labels, pertinent documentation, and continue your training.

- Implement safety measures

2. What is the hazard effect of welding?

Long-term welding fume exposure raises the risk of lung, throat, and urinary tract cancers, as well as lung damage. Metal fume fever, stomach ulcers, kidney damage, and nervous system damage are a few possible health consequences of exposure to certain pollutants.

3. What are the health hazards of being a welder?

The health hazards, and sometimes even severe health problems, of being a welder are:

- Irritation of the lungs' major airways and the throat. The gasses and tiny particles in welding fumes might dry out the throat, make you cough, or make your chest feel constricted.

- Acute asthma brought on by irritants.

- Metal fume mania.

- Severe pneumonia.

- Damage to your eyes.

4. What is the most common welding accident?

The most frequent welding damage is burns. They result from incorrect or a lack of personal protective equipment (PPE). Arc ray exposure can also cause eye injury, which is a regular risk. Bumps and wounds on the fingers and toes are additional common ailments.

5. What does PPE stand for in welding?

PPE stands for Personal protective equipment. Welders must use the proper protective gear, just like in other professions or jobs. Personal protective equipment (PPE) must generally provide protection from risks like burns, electric shock, radiation, sparks, and splatter. PPE use are a wise safety precautions and could be mandated by regulatory bodies.