My name is Nick Scarbrough. I'm a structural welder from Tennessee. I'm 34 years old and have been welding since 2015.

How I Got Into Welding

I was a butcher in a small town that had a very large industrial park located in it and all the welders would come in to buy meat from me after they got off work. I decided I wanted to start welding so when the welders would come in, I asked a few of them how to get started in the trade and one told me to get a job in a factory that had welding in the building and work my way up the ladder. That's exactly what I did.

Early Career and Progress as a Structural Welder

I started out as a machine operator and excelled at that. I was later taught to program robotic welders and plasma cutters and then was asked if I wanted to learn to weld. All of this happened in the span of around 6 months. Things progressed very quickly. I learned TIG and hardwire on stainless exhaust pipes. I worked there for around 2 years. That factory, unfortunately, shut down and moved to Mexico so I took a leap into the structural welding world.

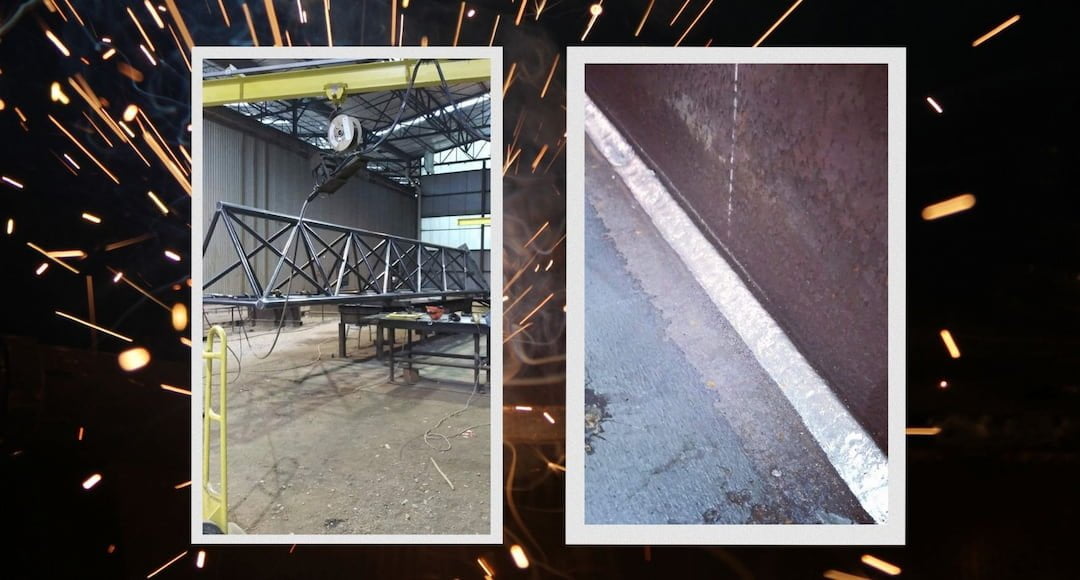

I took a low-paying job in an ironworks shop and they took a chance on me. I learned gas-shielded flux core , stick, arc gouging, crane operation and rigging, torching, fabrication, and heavy equipment operation in this shop.

I've since acquired multiple certifications and taken on a large assortment of tests. I really enjoy structural work and prefer it over most other fields of welding because of the challenges it offers. Some of the Welding Projects Carried Out

We have completed so many projects over the years that it's hard to keep count but some of them that stand out are: a huge trash guard for a dam, a rollercoaster, a nuclear facility, multiple bridges, 60,000-gallon waste water tanks, handrails and platforms, quarry ramps for dump trucks, and Mercedes Benz facilities.

Challenges in the Welding Trade

Some of the biggest challenges in this trade are: being able to be a problem solver and figure out how to make things happen without clear instructions sometimes. In addition, it's a very physically demanding job as well as mentally. A lot of times you're exposed to extreme heat or cold. You encounter getting burns on a daily basis as well.

A typical work day for me is always different. Seeing as how I'm in structural work our jobs are always changing. I do a little bit of everything. I specialize in flux core and repair work.

My Advice to Aspiring Welders

If I could give the next generation of welders one piece of advice it would be that welding isn't for everybody. You either can or you can't. There is no in-between. Some people weld for years and never master it and some are naturally gifted with a steady hand and a great amount of attention to detail. Schools only teach you HOW to weld, not how to be good at it. That's something that has to be learned, not taught.

Am I Better Off as a Welder?

Overall, welding has impacted my life very positively. My financial situation as a structural welder has greatly improved and I'm happier with my work. I usually leave work satisfied and that I've done my best on each project I take on. It's a very rewarding trade to be in.

Author: Nick Scarborough

Structural Welder