Are you a beginner welder looking to explore the world of welding but feeling intimidated by the prospect of learning and mastering sticking patterns in other welding processes? Have no fear. With this comprehensive guide, you'll be an adept welder quickly.

Table of Contents

Here, you'll find step-by-step instructions on how to get started with recognizing different welding processes and creating solid welds. From penetrating thicker metals to smoothing out complex edges – it's all here for your convenience and comfort.

Stick Welding - What Is It and Why Should You Learn It?

Stick welding is one of the oldest and most popular arc welding processes, which joins metals together using an electrically charged electrode.

The process creates a molten weld pool of metal between the two pieces of base metal being welded, with the heat generated melting both types of weld pool of metal before joining them. In addition to its simplicity and low cost compared to most other welding processes and methods, the stick welding technique is also one of the most versatile techniques, as it can be used for various metal materials.

One of the biggest advantages of stick welding is that it’s relatively easy to learn. It requires minimal equipment and training compared to other types of welding, making it an ideal choice for those new to welding.

How Does Stick Welding Work?

Stick welding, also known as shielded metal arc welding (SMAW), uses an electric current to create a short circuit between the electrode and the base material. As the current passes through the gap, it causes an arc that creates heat and melts both materials.

The melted metal pools combine and cool together as they solidify, forming a strong bond between the thinner metals of the two pieces. In addition, the stick welding process also requires a protective flux coating on the base metal and the electrode to keep it clean and protected from any impurities in the air or weld area. To begin stick welding, the stick welder must wear a welding helmet and safety gear and select a welding rod with the right electrode type. The electrode should match the welded material and the amperage welding voltage needed to generate sufficient heat for the weld.

Once the electrode is set, the welder holds it at a 90-degree angle to the material and strikes an arc. The arc creates a spark that melts both pieces of molten metal back together. The welder must then use smooth and consistent movements to guide the arc force the welding arc along the welding joint.

When the weld is complete, the welder must remove all slag and other contaminants from the weld area. Careful inspection of smooth welds for defects is also important to ensure that the welds are of high quality and the weld defects free of defects.

Stick welding is a simple yet effective welding process that can be used for both welding rods structural steel and various metalworking projects. With some practice, anyone can become an adept stick welder and master stick welding patterns.

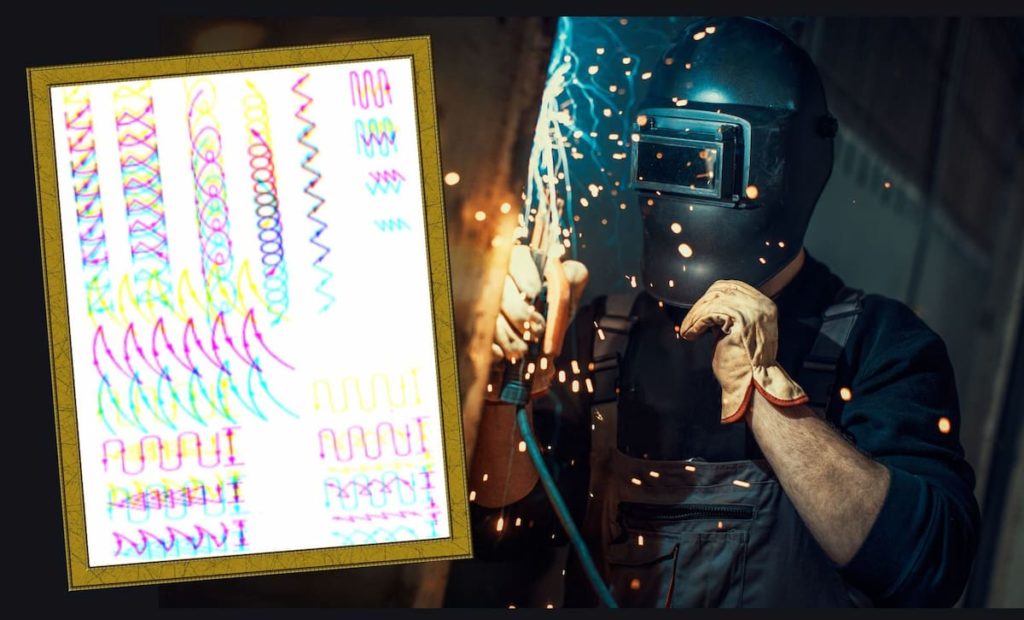

Most Used Stick Welding Patterns

Once you’ve mastered the basics of stick welding, it’s time to explore specific patterns. These patterns are used for various applications and can vary in complexity.

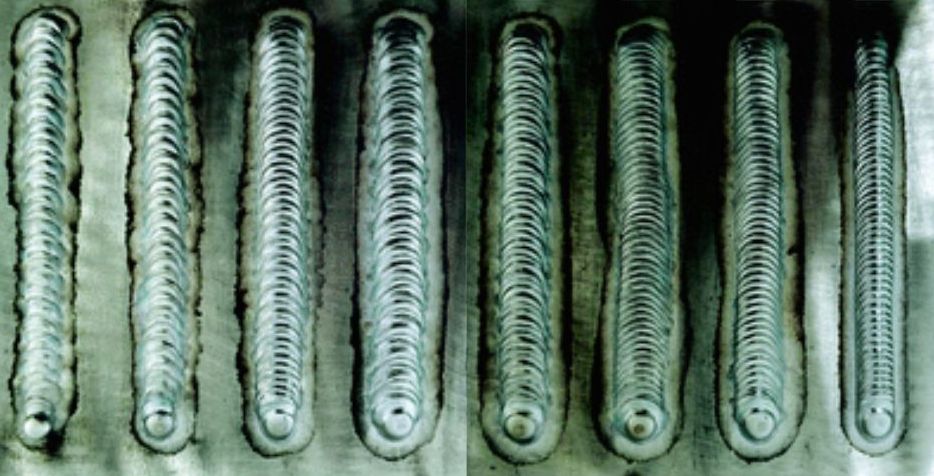

Weave

The most common sticking welding pattern is the weave. The weaving welding technique involves making a series of overlapping circles with the electrode as you progress along the stable full arc length of the weld joint. This creates an even and consistent heat distribution across the tight arc length of the weld area, which results in a strong and reliable joint.

Zigzag

The zigzag pattern is a weave variation involving a back-and-forth movement of the electrode along the weld joint. This method of vertical welding is useful for welding thick materials, as it helps to penetrate deeper layers of thicker material more easily.

Looping

Looping is another pattern that’s commonly used for thick materials. This technique involves making a series of small circles with the electrode while progressing along the arc length of the joint. The resulting weld will make the butt joint have an even, uniform appearance and provide a strong bond between thin metals and the two metals.

Globular

The spherical pattern is a technique that involves making larger circles with the electrode as you move along the weld bead and joint. This helps to distribute heat to the weld bead and metal more effectively and creates a stronger bond between the weld bead and the two metals.

Uphill Welding

Uphill welding is a technique that’s mainly used for sheet metal and thinner materials. This method involves pointing the electrode upwards as you weld, which helps prevent any spatter or slag from forming on the weld area.

Downhill Welding

Downhill welding is the opposite of uphill welding and involves pointing the electrode downward as you weld. This method of vertical arc welding tips and arc welding tips helps to create a smooth, even weld with minimal spatter or slag formation.

Slag Inclusion (Penetration) Pattern

The Slag Inclusion pattern is a technique that helps to easily weld and penetrate thicker metals. This method involves making a series of circles with the electrode as you move along the joint. The resulting weld will have an extra layer of slag on top, which helps to ensure a strong and reliable bond between the weld between two pieces.

Should I Stick Weld Downhill Or Uphill?

Whether to stick weld downhill or uphill depends on a few factors, such as the type of material being welded and the desired outcome of stick weld is: a clean metal deposit. Generally speaking, downhill welding is more suitable for sheet metals and thinner materials, while uphill welding is better for thicker materials.

It's important to note that each welding technique has advantages and disadvantages, so it's best to practice both and determine which works best for your needs. With some practice, you'll soon become an expert in stick-on welding techniques and be able to produce reliable welds on any material.

In conclusion, stick welding is a great way to easily join two pieces of metal together overhead welding them. Its versatility travel speed and simplicity make it an ideal choice for those new to stick welding techniques and those looking for a reliable stick welding together method.

FAQS

What are the benefits of welding?

Welding offers a highly efficient and economical approach to join two metal pieces together. This versatile technique finds utility in diverse applications and frequently yields stronger bonds compared to alternative metal joining methods like riveting or bolting.

To accomplish welding, you will require a welding machine. It is crucial to consider the welding position, which determines the orientation and angle at which you perform the weld. Furthermore, the choice of filler metal is essential as it contributes to the strength and integrity of the weld.

What type of welding is the strongest?

TIG welding is often considered to be the strongest form of welding, due to its ability to produce a strong weld puddle that is both clean and relatively free from porosity Compared to MIG welding, TIG welding requires a higher of expertise as it involves more precise control and maneuvering the TIG torch. However, it produces a much stronger weld joint than MIG welding, making it ideal for demanding applications.

TIG welding requires the use of a shielding gas to protect the weld puddle and surrounding area from oxidation. The shielding gas is fed through the nozzle of the TIG torch in order to create an inert atmosphere around the weld puddle, which helps reduce porosity and improve overall weld quality.

How do you stick weld?

Stick welding is one of the most common methods used to join two pieces of metal together. To improve your stick welding, there are several things you should consider:

- You can use a wire brush to prepare the surface before you begin your weld. This will help ensure a good bond between the metals.

- Make sure that you position the rod in a flat position. Using a specific rod angle will result in less accurate welding, and can even cause the rod to become hot and melt.

- Shielding gas is also essential for stick welding. It helps protect the weld pool from oxygen and other atmospheric gases which could potentially ruin your welds.