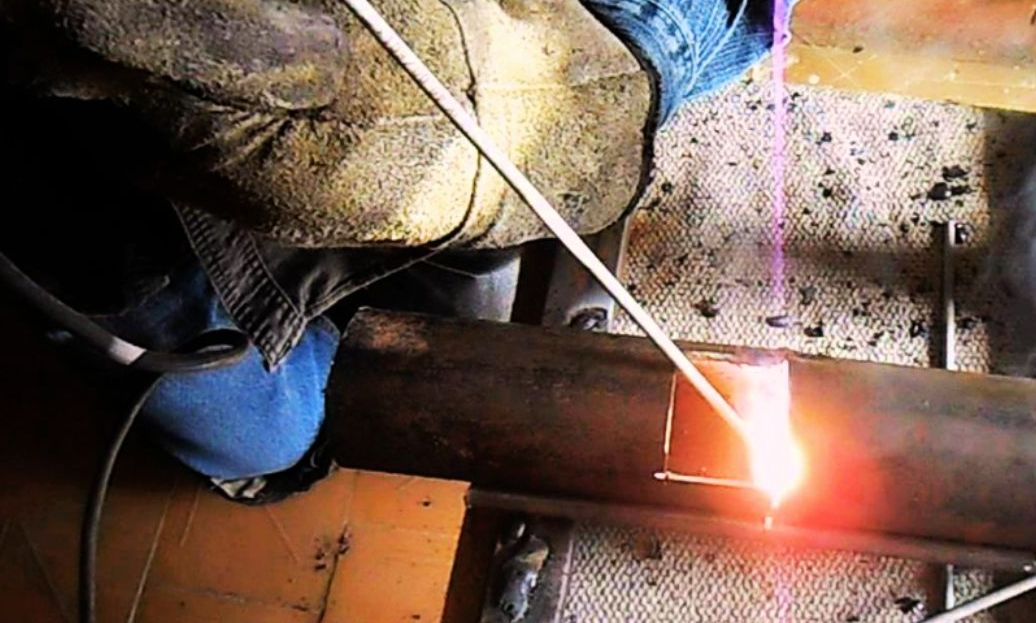

Are you seeking a reliable, strong, long-lasting material for your welding projects? Look no further than cast iron welding rod! This versatile metal has been used in various industrial processes, offering excellent performance in any situation.

Table of Contents

From bridge building to automotive repairs, cast iron welding rod is the go-to choose base metal used for many professionals. Its distinctive properties, including low melting point, increased durability, and rust protection, make this metal an attractive option for structurally important components.

In this blog post, we will explore the different benefits cast iron welding rods provide and look at their strength, versatility pre heat, and corrosion resistance properties.

What Is the Best Welding Rod for Cast Iron?

When welding cast iron, the most suitable rod is a low-hydrogen electrode such as electrodes such as an E7018 or E8018. These rods and electrodes are designed specifically for welding this type of material and provide superior weld strength and crack resistance than other types of electrodes.

The low-hydrogen element also helps minimize distortion by reducing hydrogen embrittlement. Remember that the rod size and length should be chosen carefully to ensure a strong, uniform weld and minimal slag buildup. Make sure you use the right quality, size, diameter, length and type of carbon for your project!

Stick Welding Rods for Cast Iron

The two stick welding with electrode is the most common welding process and rod for welding the castings of iron. This two stick welding form uses two stick welding an electrode of a metal core covered weld metal and in flux.

The gas flux helps to protect the gas welds and pool from atmospheric gas contamination and provides good flame penetration, while the metal core ensures good electrical conductivity to produce a strong arc.

ENi-CI

ENi-CI is a type of cast iron welding rod designed specifically for use on applications requiring wear and corrosion resistance. It offers excellent weld strength, crack resistance, and superior mechanical properties.

Its high carbon content allows it to be used in demanding applications such as marine environments, while its low hydrogen content helps reduce the risk of hydrogen embrittlement.

ENi-CI also offers superior corrosion resistance, making it ideal for welding projects requiring frequent moisture exposure and other elements.

ENiFeMn-CI

ENiFeMn-CI is a type of cast iron and nickel welding rod that offers superior strength and durability compared to other types of white welding cast iron, and white iron and nickel rods. It features a combination of nickel, iron, manganese, and chromium, making the surface of the weld more stable and resistant to cracking or weakening.

The rod also has excellent corrosion resistance and a higher melting point than other welding rods commonly used. Additionally, it is more economical than other welding rods as it requires less side welds and preparation pre heating before use.

Due to its superior strength, durability, and corrosion resistance properties over nickel, ENiFeMn-CI is a great choice for heavy-duty applications such as bridge or automotive repairs.

ENiCu

ENiCu is a cast iron arc welding rod with superior strength and corrosion resistance. Its combination of nickel, copper, and chromium makes crack resistant, it brittle and it ideal for high-temperature applications where heat input must be tightly minimized.

This rod also offers excellent electric arc and stability and steady bead formation, which helps with heat stress reduce spatter during welding process. It is also highly resistant to cracking cracks and breaking during machine operation, making it ideal for applications requiring long-lasting welds.

This rod type requires minimal surface preparation before use and can be used in various applications, such as automotive repairs or bridge building, where superior performance and quality is required to save time afterwards.

How to Choose the Proper Rod

The correct rod choice for cast iron welding ensures a strong, durable, flat, welded part. Low-hydrogen electrodes such as E7018 and E8018 are the most suitable options for this type of weld metal material.

It is important to carefully consider the size of the rod to achieve a uniform, flat, weld area and minimal slag buildup in weld pool. Stick electrodes are also popular for cast iron arc welding because they protect the various welds and pool from atmospheric contamination and provide good penetration.

Specialty rods designed specifically for this application, such as ENi-CI, ENiFeMn-CI, and ENiCu, can offer superior strength and corrosion resistance properties. Additionally, these rods require minimal preparation pre heating before use and are ideal for high-temperature applications.

Can You Use Stainless Steel Rods to Weld Cast Iron?

No, stainless steel rods are not suitable for welding cast iron. This is because stainless steel has a higher melting point than cast iron and will not create a strong enough bond with cast irons for the carbon when welded to metal to withstand welding stresses.

Additionally, using heated stainless steel rods and electrodes on cast iron could cause the metal to crack due to thermal shock. Stick electrodes specifically designed for cast iron welding should be used instead. These rods and electrodes have a lower melting point and will provide a stronger, more reliable, welds, than stainless steel rods and electrodes.

FAQs

What is cast iron welding rod used for?

Cast iron: welding cast iron rod, or welding cast iron part, is used for welding structural components such as bridges, automotive parts, and other heavy-duty applications. Its low melting point and increased durability make it an attractive repair choice.

What are the benefits of using cast iron welding rods?

The benefits of using cast iron welding rods include its strong weld strength, thermal expansion before heat through, superior crack resistance pre heat through, and corrosion resistance preheat through. It also requires minimal preparation before use and is suitable for high-temperature applications shielded metal arc welding.

What are some tips for using cast iron welding rods?

Choosing the right size and type for your project is important when using cast iron welding rods. Low-hydrogen electrodes such as E7018 or E8018 are ideal for this application. Additionally, specialty rods such as ENi-CI, ENiFeMn-CI, and ENiCu offer superior strength and corrosion resistance properties over casting them.

Can you use a welder to repair cast iron?

Yes, it is possible to use a welder to repair cast iron parts and components. A stick welding welder is the most common choice for stick welding cast iron in this application. Choosing the stick welding the right type and size of electrode is important to ensure a strong, reliable weld.